Many industries in order to decrease air pollution are using innovative technologies. Among these, Electrostatic Precipitator stood out as a powerful tool against air pollution. It contributes to environmental sustainability by reducing emissions and maintaining air quality standards.

Electrostatic precipitator is used for efficient removal of fine particles matter, including dust and pollutants, from industrial exhaust gasses. Its main uses are in different kinds of sectors where maintaining air quality is important.

So let’s see in this article and discuss what is electrostatic precipitator, its working principle, electrostatic precipitator diagram, its applications and advantages and disadvantages.

What Is Electrostatic Precipitator

An electrostatic precipitator is a filtration device that removes fine dust particles and pollutants from the flowing gas stream. It is an air purification tool which uses electrical forces to remove tiny microscopic particles from many industrial emissions.

Electrostatic precipitator is used for controlling the air quality by capturing and removing particles and maintaining cleaner air and reducing the effect of industrial activities on the environment.

It works on the principle of electrostatic attraction, using electric fields to charge particles in the gas stream. Charged particles are then attracted to and deposited onto collection surfaces, typically electrodes or plates.

There are many uses of electrostatic precipitator in thermal power plant as they are used for removal of ash particles which are produced as by-products by thermal power plants. These ash particles create many environmental problems.

That’s why an electrostatic precipitator in thermal power plant is placed to catch and remove these ash particles before the flue gasses are released into the atmosphere.

Other than dust particles, ash, smoke, electrostatic precipitator can remove metallic particles, chemical products, waste residues, cement and mining dust as well.

You May Also Like To Read : Laminar Air Flow Working Principle

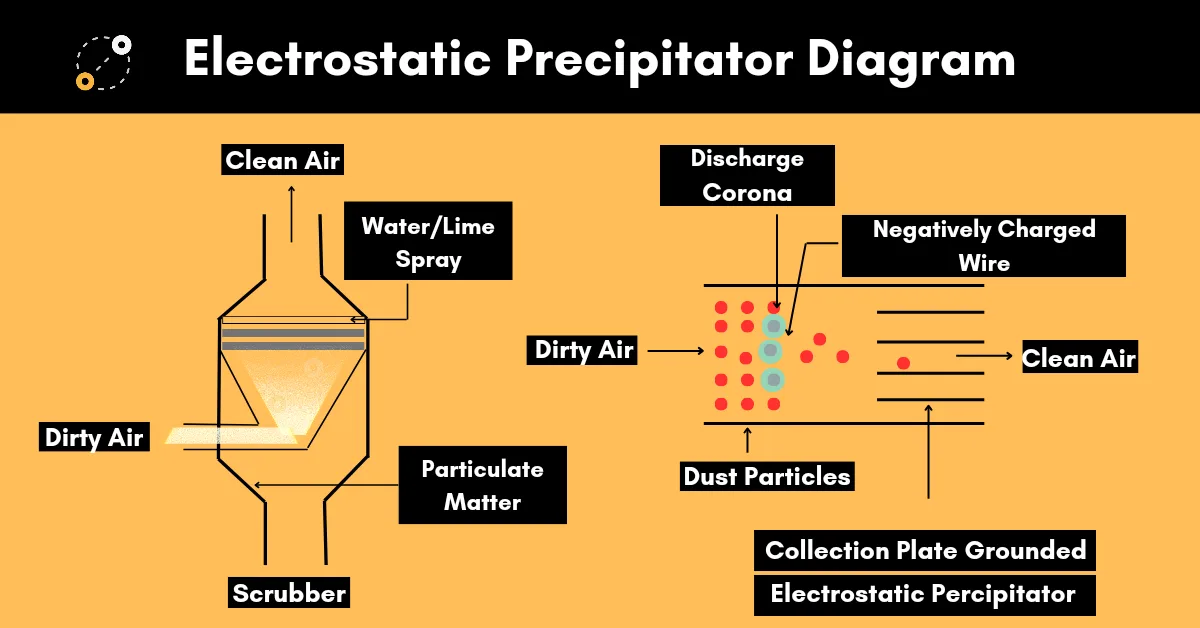

Electrostatic Precipitator Diagram

Electrostatic Precipitator Working

An Electrostatic precipitator working is quite simple. The electrostatic precipitator working principle is based on the concept of electrostatic attraction and repulsion.

The working of an electrostatic precipitator involves the use of electrostatic forces with which the it can remove and capture airborne particles from an industrial gas stream.

Here is a step-by-step explanation of electrostatic precipitator working –

Particle Charging

The working of an electrostatic precipitator begins with the introduction of the industrial gas stream, containing airborne particles, into the precipitator. High-voltage electrodes, usually made of wires or plates, are placed in the precipitator.

Ionization Section

Another step in the electrostatic precipitator working principle is the Ionization section. In the ionization section, the electrodes are charged with a high voltage. This creates a corona discharge or ionization zone, where electrons are removed from gas molecules, producing ions.

Electrostatic Field Formation

The charged electrodes generate a strong electrostatic field in the gas stream. As the gas passes through this field, the negatively charged ions created in the corona discharge attach themselves to the airborne particles, imparting a negative charge to the particles.

Particle Migration

The charged particles, now negatively charged, experience a force (Coulomb force) in the presence of the electric field. This force causes the particles to move towards the positively charged collection surfaces of the electrostatic precipitator, typically grounded plates or tubes located downstream of the ionization section.

Particle Collection on Plates

Another step in the electrostatic precipitator working is collection of particles on the plates. The charged particles are collected on the grounded plates, effectively removing them from the gas stream. The particles stick to the collection surfaces due to the electrostatic attraction between the negatively charged particles and the positively charged plates.

Vibrations

The working of an electrostatic precipitator also includes vibrations to prevent excessive build up and maintain efficiency. Over time, the collected particles form a layer on the collection surfaces. In this mechanism, an electrostatic precipitator can remove the collected particles, allowing them to fall into holders at the bottom of the precipitator.

Particle Disposal

The removed particles collected in the holders are periodically removed and disposed of properly for the proper working of the electrostatic precipitator. This makes sure that the it continues to operate efficiently and effectively.

Clean Gas Discharge

The last step in the electrostatic precipitator working is the discharge of clean gas. The gas stream, now empty of particulate matter, exits the precipitator as cleaner, pure air. This purified air can be released into the atmosphere or for additional treatment processes, depending on the specific requirements of the industrial facility.

Types Of Electrostatic Precipitator

There are four main types of Electrostatic precipitator –

Plate or Flat-Plate Electrostatic Precipitator

This is one of the most common types of Electrostatic precipitator. Plate electrostatic precipitator consists of a series of flat, horizontal plates, made of metal, arranged vertically with gaps between them. The gas stream passes between these plates, and high-voltage electrodes are maintained on either side.

The particles in the gas stream are charged and then collected on the plates, effectively removing them from the air.

Tubular Electrostatic Precipitator

In a tubular Electrostatic precipitator, the collection surfaces are in the form of cylindrical tubes instead of flat plates. The tubes are suspended vertically, and the gas stream passes through them. Similar to the flat-plate design, high-voltage electrodes are positioned on either side of the tubes.

Wet Electrostatic Precipitator

This is among those types of Electrostatic precipitator which uses water or other liquid into the collection process. The particles are charged, and then water is used to neutralize the charge and remove them. A Wet electrostatic precipitator is effective in handling sticky or corrosive particles and are used in applications where dry electrostatic precipitators may face problems.

Dry Electrostatic Precipitator

The traditional types of electrostatic precipitator discussed earlier are considered dry precipitators as they operate without the use of liquid in the collection process. Dry electrostatic precipitator is commonly used for removing dry, non-sticky particulate matter.

Applications Of Electrostatic Precipitator

- An Electrostatic precipitator is used for removing particulate matter and smoky soot.

- Electrostatic precipitators are used in air conditioning systems to filter the air.

- An Electrostatic precipitator in thermal power plant are used to control the emission of fly ash and other particulate matter generated during the combustion process.

- Metal Smelting and Processing, industries use electrostatic precipitator to catch and remove metallic particles and fumes generated during the smelting activities.

- Electrostatic precipitator is used for cement plants. They are used to control the release of particulate matter and regulate environmental regulations.

- Chemical Manufacturing, it is used for chemical production facilities to control emissions of particulate matter. An electrostatic precipitator can remove chemical by-products as well.

- Electrostatic precipitator is used for waste incineration. They manage the release of pollutants, including ash particles, during the incineration of solid waste.

- Oil Refineries, it is another great use of an electrostatic precipitator. They control emissions from many processes, including fluidized catalytic cracking units and sulfur recovery units.

- An Electrostatic precipitator is used for removing materials, mists, and explosive dusts from the fumes as well.

Advantages Of Electrostatic precipitator

Electrostatic Precipitators have many advantages in the control of airborne particulate matter and pollutants in various industrial processes. Here are some key advantages of electrostatic precipitator –

- An Electrostatic precipitator can remove fine particles, including sub-micron particles, from the gas stream, often controlling 99% of the pollution.

- An Electrostatic precipitator generally have lower operating costs compared to other air pollution control technologies.

- They require less maintenance.

- Consume less energy, contributing to overall process efficiency.

- Electrostatic precipitator is used for handling large gas volumes.

- Wet electrostatic precipitator is used for capturing sticky or corrosive particles and uses liquid to neutralize the charge and remove these particles efficiently.

- It has a long service life.

- Electrostatic precipitators are compatible with various fuel types, including coal, biomass, oil, and gas.

Disadvantages Of Electrostatic precipitator

- An Electrostatic precipitator has an initial cost for installation.

- They have a complex design, regular cleaning and inspection of electrodes and collection surfaces is necessary.

- An Electrostatic precipitator requires large space for installation.

- The high voltage electrodes and collection surfaces may be susceptible to corrosion and erosion over time.

Conclusion

An Electrostatic precipitator is a great instrument for reducing air pollution in many industries. Its long service life, compatibility, and the ability to handle pollutants is important for the changing environment. An Electrostatic precipitator is used for removing particulate matter, its diversity in application, and ability to contribute to environmental sustainability make them essential for cleaner air emissions.

FAQs

What is an electrostatic precipitator used for?

It is used for filtration of polluted air to make it clean.

What is the use of electrostatic precipitator in automobile?

In automobile it is used to removed the solid particulates from the emission of exhaust gas from engines of the automobiles