Laminar air flow is the smooth movement of air in a designated space having a uniform velocity and direction. In laminar air flow, air flows in parallel layers with minimal turbulence.

Just like a gentle breeze that flows smoothly or a river flowing straight, in laminar air flow, the air is moving in a neat and organized way, so particles don’t get mixed up and cause problems.

Laminar airflow systems are used in settings such as laboratories, operating rooms, etc. where a contamination-free environment is necessary. But how do these systems work, what are laminar air flow principle, advantages and disadvantages ? Let’s find out.

what is laminar air flow

The laminar air flow definition can be stated as, a controlled and steady movement of air in which the air flows in parallel layers with a uniform velocity and direction, without turbulence or swirling.

Sir John Charnley popularized laminar air flow (LAF) ventilation systems for use in operating rooms in the 1960s during joint replacement implants after a series of trials revealed a significant reduction in infections due to the use of laminar flow.

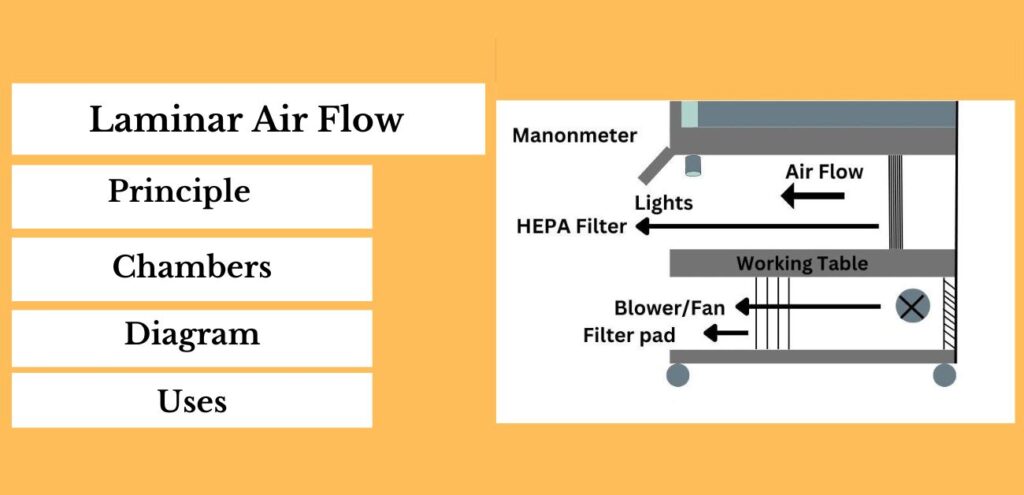

laminar air flow diagram

You May Also Like : Types Of Incubator And Their Function In Microbiology

laminar air flow chamber

A laminar air flow chamber also known as a laminar flow cabinet, clean bench, tissue culture hood or laminar flow hood is an enclosed workspace covered in a box-like structure that uses the principle of laminar airflow to create a controlled and sterilized environment.

Parts Of Laminar Air Flow Chamber –

A laminar air flow chamber consists of different essential parts that work together to create a controlled, clean and a safe environment. The following parts are –

Cabinet Structure

The main structure, enclosure of a laminar air flow chamber is a box typically made of stainless steel with a glass screen in front or other smooth and easy-to-clean materials. The glass screen in front of the box opens fully or partially using hinges or sliders.

This cabinet structure carries all the internal components and provides a strong framework for the laminar air flow chamber.

Work Area

A flat work area inside the chamber, acts as a stable platform for operations such as growing of microorganisms, the creation of electrical wafers, and plant tissue. It helps in stabilizing other equipment, such as burners, samples, and culture plates.

The laminar air flow chamber work area is typically made of stainless steel. The reason for this is that stainless steel is durable and resists rusting and corrosion well.

HEPA Filter

HEPA (High-Efficiency Particulate Air) filter is the most important part of the laminar air flow chamber which is located right next to the cabinet structure and is divided by a mesh.

This filter functions as the final filter and even removes 0.3 micron-sized particles and microorganisms from the incoming air, ensuring that the air inside the cabinet is clean and sterile.

It functions in the three following mechanisms –

Interception – In this large particles are captured, sticking to the HEPA filter’s fibers.

Diffusion – The impurities travel in a Brownian motion and get caught within the filter fibers.

Impaction – Medium-sized particles are tossed around in conflicting micro airstreams during and the fibers catch them.

Pre-Filter

Also known as filter pad, it acts as the first filter and is directly in contact with the external environment. Pre-filters are typically concealed behind a mesh or grill and are situated either on top of the cabinet or just below the work surface towards the front.

It captures larger particles and prolongs the life of the main HEPA filter. Large fiber holes in it allow it to catch airborne particles as large as 5 microns.

Blower or Fan

A fan or a blower sucks the air in from the pre-filter and processes it through the HEPA filters. It is located between the filter pads and directs the air into the workspace in a smooth and controlled manner.

UV Lamp

The UV lamp emits ultraviolet (UV) light, which is naturally cancerous. It kills living protein, induces abnormal cell growth, and filters microbes smaller than 0.3 microns.

Before and after use, the chamber must be completely exposed to UV light. The chamber and all other equipment inside it, such as Petri dishes, test tubes, beakers, watch glasses, etc. are cleaned by the UV lamp. At the very least 15 minutes prior to the procedure, the UV light should be turned on.

Control Panel

A control panel allows the user to adjust the fan speed, turn the cabinet on/off, and sometimes control other parameters such as lighting or alarms.

Illumination Lamp

There is a built-in lighting to illuminate the workspace, helping in visual tasks and maintaining a well-lit environment. Its main role in a laminar air flow chamber is to produce adequate lighting inside the chamber.

Airflow Plenum

This is the space behind the HEPA filter where the air is collected before being forced through the filter and into the workspace. It ensures a uniform distribution of filtered air.

Airflow Indicator

Some cabinets feature airflow indicators or monitors that display the status of the laminar airflow and the condition of the HEPA filters.

laminar air flow principle, working, and uses

Laminar Air Flow Working

The working of a laminar airflow chamber follows a specific sequence to create a controlled and sterile environment. Here’s the step-by-step sequence of how a laminar airflow system operates –

- The cabinet should be checked to make sure there are no UV-sensitive materials inside before running the laminar flow chamber.

- The UV light is then turned on and the glass screen of the chamber is closed. The UV light should be kept on for 15 minutes to make sure that the surface of the working bench is sterile.

- After turning off the UV light, the air flow is turned on after 10 minutes. The airflow is turned on 5 minutes before the start of the procedure.

- Air Intake – The process begins with the intake of surrounding air into the laminar airflow chamber.

- Pre-Filter – The air passes through a pre-filter that captures larger particles and contaminants, preventing them from reaching the main filtration stage.

- HEPA Filtration: The incoming air is then directed through a HEPA filter removing dust, allergens, bacteria, and other microscopic contaminants.

- A fan or blower inside the system creates a consistent flow of filtered air.

- The filtered air is directed in a specific pattern, either vertically (top to bottom) or horizontally (side to side), depending on the design of the laminar airflow chamber.

- The air flows in parallel layers with a uniform velocity. This laminar airflow ensures that particles and microorganisms are pushed away from the work surface, maintaining a contamination-free zone.

- Users can now perform tasks within the sterile workspace. They can manipulate samples, conduct experiments without the risk of contamination.

- UV Lamp – UV lamp produces ultraviolet light. This additional step further disinfects the workspace by inactivating microorganisms that might be present.

Laminar Air Flow Principle

The principle of laminar air flow is based on the concept of laminar flow of air. If the gas molecules are traveling through the air in a series of parallel straight lines, the flow is called laminar. Throughout the journey, the gas molecules do not collide.

It employs a high-efficiency particulate airflow system that captures and removes all kinds of airborne impure particles in order to maintain a clean and sterile atmosphere.

Laminar air flow’s ability to produce uniformity in velocity and direction in an enclosed space gives developers the chance to develop an effective circulation system based on the principle of laminar flow.

laminar air flow uses

The Laminar air flow uses can be seen in various industries and applications. Some of the key laminar air flow uses are –

Cleanrooms – Laminar air flow chamber is used in cleanrooms across industries such as pharmaceuticals to prevent contamination during production, research, and assembly processes.

Laboratories – Research laboratories use laminar air flow systems for tasks like cell culture, sample preparation, and delicate experiments that require a sterile environment.

Tissue Culture – In tissue culture laboratories, laminar airflow provides a sterile environment for growing plant and animal cells for research and commercial purposes.

Microbiology: The use of laminar air flow can be seen in microbiology laboratories. It minimizes the risk of cross-contamination and ensures the accuracy of results.

Medical Research – Laminar air flow chambers are used in medical research settings for tasks such as DNA analysis, protein purification, and other molecular studies.

Food Processing – Laminar air flow is employed in food processing facilities to maintain a clean environment during the handling and packaging of food products.

Semiconductor Industry – One of the Laminar air flow uses is in the production of semiconductors to prevent particle contamination that could impact the performance of microelectronic devices.

Forensics: Another important use of laminar air flow is in forensic laboratories, it helps prevent cross-contamination during DNA analysis and evidence handling.

Pharmaceutical – The pharmaceutical industry depends on laminar air flow for aseptic processing, ensuring the sterile manufacturing of drugs and preventing contamination.

Types of laminar air flow

There are two main types of laminar air flow chamber, vertical laminar air flow chamber and horizontal laminar air flow chamber. These systems are designed based on the direction of the air flow.

Vertical Laminar Air Flow

In a vertical laminar air flow chamber, the air enters from the top of the chamber and flows downward in a uniform, unidirectional manner towards the bottom of the chamber.

A vertical air flow requires less depth and floor space, making it easier to maintain and reducing the chance of blocked air flow or the transfer of polluted air downstream.

The downward air flow helps prevent particles from entering the workspace, minimizing the risk of contamination.

Vertical laminar air flow chambers are often used in environments such as biological safety cabinets, laboratory workstations, and clean benches.

Horizontal laminar air flow

In a horizontal laminar air flow chamber, air is introduced from one side of the workspace and flows horizontally across the work area before exiting on the opposite side.

One benefit of a horizontal laminar air flow chamber is that the air flow horizontally to the workspace purifies the area with a constant velocity.

Horizontal laminar air flow chambers are commonly used in industries such as electronics manufacturing, where sensitive components need to be protected from contaminants during testing processes.

Other than the above two, there is also a Reverse laminar air flow. Reverse laminar air flow, also known as “negative pressure laminar air flow,” is a controlled ventilation system that operates opposite to typical laminar air flow arrangement.

In this system, clean air is drawn from an uncontaminated area and directed towards a designated contaminated or hazardous space, creating a zone of lower pressure relative to its surroundings.

laminar air flow advantages and disadvantages

Laminar air flow chamber offer several advantages and disadvantages, depending on the specific application and requirements such as –

Advantages

Precision and Consistency – Laminar air flow ensures uniform and controlled air distribution, maintaining consistent conditions for experiments, measurements, and processes that require accuracy.

Laminar air flow systems come in many different types, such as vertical and horizontal laminar flow, allowing for adaptation to different tasks and environments.

In healthcare settings, laminar air flow chambers are used in operating rooms and isolation rooms to control the spread of airborne pathogens, reducing the risk of infections and disease transmission.

Another advantage of Laminar air flow is that it’s energy efficient. Less energy is lost through friction and turbulence because air particles flow smoothly and parallel to one another.

Disadvantages

Laminar air flow can generate heat, which might affect the comfort of operators working within the chamber.

The initial cost of purchasing and installing laminar airflow equipment can be relatively high, especially for specialized systems like biological safety cabinets.

Laminar air flow chambers require regular maintenance, including filter replacements, to ensure their effectiveness.

Another disadvantage of laminar air flow is that it has a low rate of heat and mass transmission. It has limited intermixing and slower transfer rates compared to turbulent flow, which exhibits high rates of heat and mass transfer due to quick mixing and energy dissipation.

Laminar air flow is sensitive to disturbances. It can be easily disturbed by external sources, such as vibrations or flaws in flow channels, unlike turbulent flow, which can self-stabilize following disturbances.

laminar air flow in microbiology

In the field of microbiology, where we study microscopic living bodies like bacteria and viruses, it’s important to maintain cleanliness and safety.

Laminar air flow technology, characterized by its controlled and clean air movement, by providing a contamination-free environment is essential in microbiological laboratories.

By providing a barrier against airborne contaminants, this device protects delicate cultures, experiments, and processes from outside intervention.

Laminar airflow helps keep samples pure, minimize cross-contamination, and maintain the accuracy of research findings in the complex field of microbiology by creating a finely directed flow of filtered air.

Laminar Air Flow Uses In Microbiology

Laminar air flow is incredibly useful in the field of microbiology for creating a clean and safe environment. Some of the laminar air flow uses in microbiology are –

Drug Sensitivity Testing – Laminar air flow chambers help in performing drug sensitivity tests, where microbial strains are exposed to different antibiotics to determine their sensitivity.

Microbial Culture – Laminar air flow hoods provide a sterile space for cultivating and studying microorganisms, such as bacteria, yeast, and fungi. This prevents cross-contamination and maintains the purity of cultures.

Sample Preparation – Laminar airflow cabinets are used for aseptic sample preparation, reducing the risk of introducing unwanted microorganisms during media preparation, dilutions, and inoculations.

Virology Research – Laminar air flow systems prevent the spread of viral particles during research involving viruses, contributing to biosafety and protecting researchers.

Cell Culture – Microbial cell culture work benefits from laminar air flow, providing a controlled environment for growing cells and preventing contamination.

laminar flow and turbulent flow

Laminar flow and turbulent flow are two different types of fluid flow patterns that describe how a fluid (such as air or water) moves. These patterns have distinct characteristics and occur under varying conditions.

As already, discussed above Laminar flow is a smooth and orderly movement of a fluid in parallel layers. In this type of flow, the fluid particles move in a regular manner, with each layer gliding next to the other without mixing.

It often occurs at low velocities or in small, well-defined spaces. Imagine water flowing gently in a straight pipe without any ripples or disturbances – that’s an example of laminar flow.

Whereas, a Turbulent flow is a flow where the fluid particles travel in a zigzag pattern. The fluid particles don’t follow orderly paths. Instead, they swirl, mix, and create unpredictable eddies and fluctuations, which results in loss of energy.

In a turbulent flow, the intensity and direction of the fluid’s speed at a given point are changing continuously. Large diameter pipes with high velocity fluid flow are more likely to experience turbulent flow.

Imagine a fast-flowing river with swirling water and lots of ripples – that’s an example of turbulent flow.

laminar air flow price

The laminar air flow price can vary based on factors such as the type of equipment, size, features, brand, and customization.

The Vertical laminar air flow chamber price can start at around INR 75,000 to 2,25,000 for basic models and can go up to several lakhs of rupees for larger or advanced chambers.

For medium-sized vertical laminar air flow chambers with additional features and specifications, prices can range from INR 2,25,000 to 6,00,000 or more.

Similar to vertical chamber, Horizontal laminar air flow chamber price can start around INR 30,000 to 60,000 and go higher up to INR 60,000 to 2,00,000 or more based on size and features.

Conclusion

Laminar air flow chamber serves as a shield against contamination, safeguarding experiments, samples, and products from airborne particles. By maintaining a sterile environment and consistent conditions, it ensures accurate results. Whether in laboratories, healthcare, or manufacturing, laminar air flow’s contamination control and operator safety benefits contribute to developments and reliable outcomes.

Also Read :

- What Is Hybrid Computer?

- Science City Kolkata Timing, Photos And Ticket Price

- Synthetic Seed Overview